Low emissivity glass

Thermal protection and solar control.

The Low-E glass can help with improving thermal and solar performance. It’s possible by using passive and solar control low-e coatings on glass.

PRESS GLASS recommends using various Low E coatings to help manage the heat coming into a building during the summer months as well as keeping as much light in as possible during the winter months.

Passive low-e coatings

Thermal comfort thanks to perfect thermal insulation.

Solar heat gains in the wintertime or protection against the heat in summertime

In the winter

Thermal protection is the basic task of insulated units. Thanks to our partnership with suppliers, resulting in development of new glass coatings, PRESS GLASS is able to offer glass panes with very low solar gain coefficient, close to the value of heat transfer coefficient of walls. Cold feet near the window are in the past. All the people who want to save on heating in winter thanks to solar heat gains from the sunlight coming through window panes and are not concerned with overheating in summer, can now purchase heat insulating window panes with an increased coefficient of 73%.

In the summer

In the summer the sun emits much larger quantities of thermal energy, than in the winter. Overheating is observed, mostly due to the heat transfer through window panes. The grade of summer overheating protection is expressed as the solar heat gain coefficient or SHGC. Its lower value defines better efficiency of the protection against overheating.

Our offer of heat-insulating glass units includes make ups that can reduce the overheating effect by offering a SHGC of 37%. Now we can improve thermal comfort while reducing the operating costs of air conditioning units. It is worth remembering that cost of cooling the premises are higher than cost of heating. Nevertheless one disadvantage of low emissivity insulated units with low SHGC is also the low light transmission.

In summer & winter

Due to disadvantages associated with overheating in the Summer or underlighting in the Winter when the low emissivity glass is used, PRESS GLASS recommends the application of solar control glass as the main functional layer in all the types of buildings.

Solar control low-e coatings

For many years architects and designers have been looking for new construction materials that would open up the commercial and residential buildings to the exterior world. They have been fascinated with the properties of glass which proved to be the perfect construction material for the modern era.

It offers quality and beauty, helps save energy, and allows for easy assembly. Among its various qualities, there is one which is especially useful for offices and public facilities, namely solar protection. Low E coatings add character to a building and reduces undesirable heating of the elevation regarding a type of coating.

Advantages

Optimal temperature in rooms

The level and distribution of air temperatures has a significant impact on our comfort while indoors. Until recently it was possible to feel a dramatic drop in temperature near a window during the winter, which could produce a strong feeling of discomfort. Thanks to the application of thermal low-e insulated glass units it is possible to eliminate this problem.

A different problem can arise in the summer, when the sun’s rays overheat the inside of a building. This problem can be rectified by low-e solar control glass which, thanks to its special construction, limits overheating while maintaining a high level of light transmission. A similar function is also provided by thermal low-e glass, but to a lesser degree; this is compensated by the benefit of higher heat retention performance during winter that low emission glass with passive coatings offers.

Reducing the costs of air conditioning

During the summer months, it can become very costly to keep a building cool and comfortable. This can be especially difficult when you have glass on the southern facing facade that is regularly subject to the heat of the sun. With the cost of cooling a building being higher than that of heating it, the use of Low E glass to control that passive solar heat is especially important to regulate cooling costs.

So as to reduce the costs of cooling it is necessary to apply low-e solar control glass in windows and facades of buildings.

Reducing the light transmission

The application of such glass, especially that which is dyed in mass during the winter period can cause reduced light transmission to a building especially on the northern side.

In order to preserve the high level of light transmission, as well as significantly reducing the infiltration of solar energy it is necessary to low-e solar control glass.

Market offering

Structure and coefficients of Low-e solar control insulated units produced by PRESS GLASS.

We offer quality Low-E products from these renowned suppliers. Please visit their site for the full and up-to-date market offer.

LOW-E SOLAR CONTROL GLASS ADVANTAGES SUMMARY

Videos

Solar energy transmission

Light transmission

Facade glazing

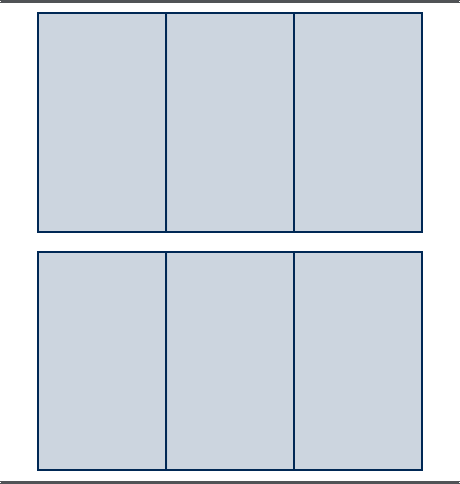

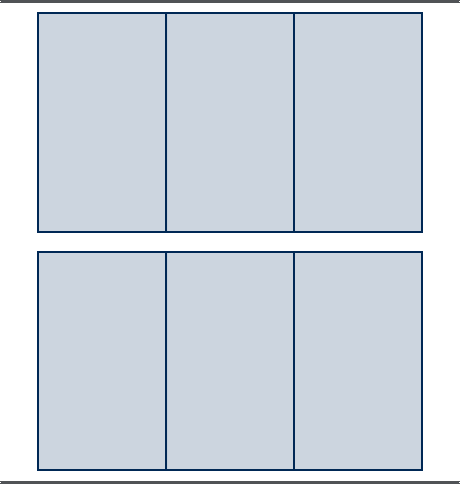

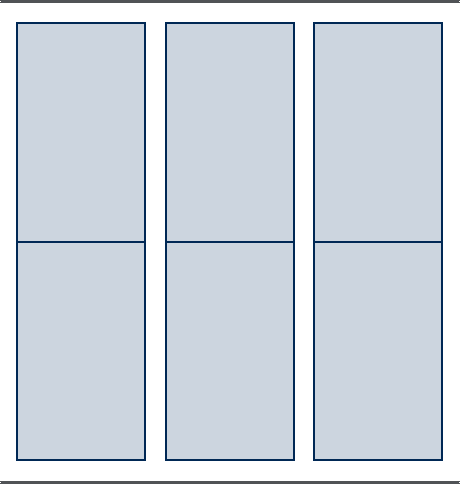

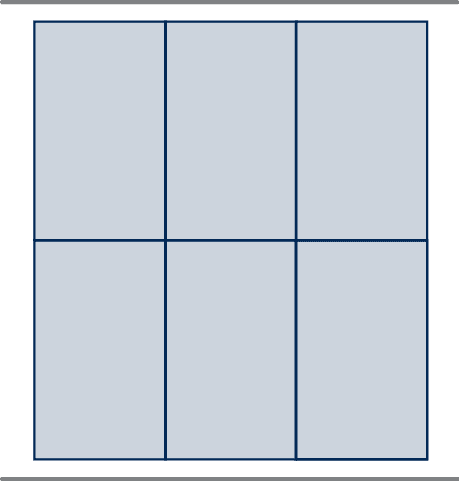

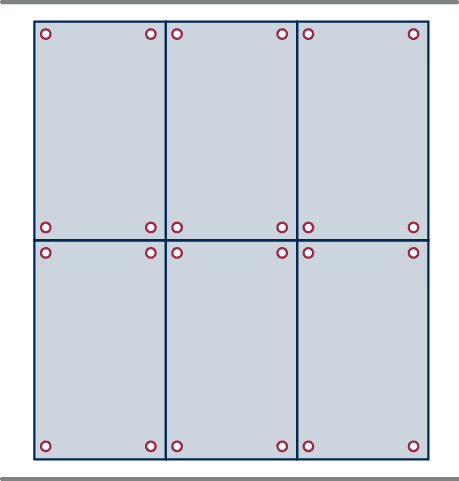

PRESS GLASS produces insulated units for all construction systems:

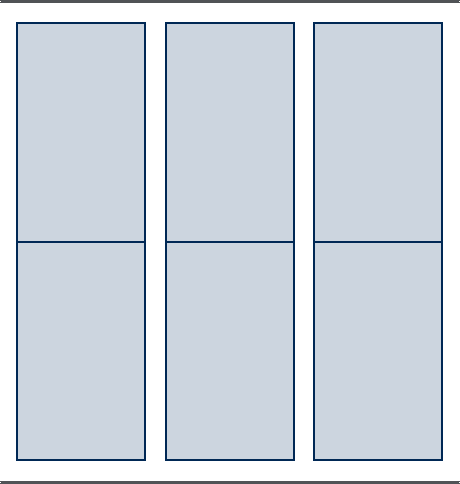

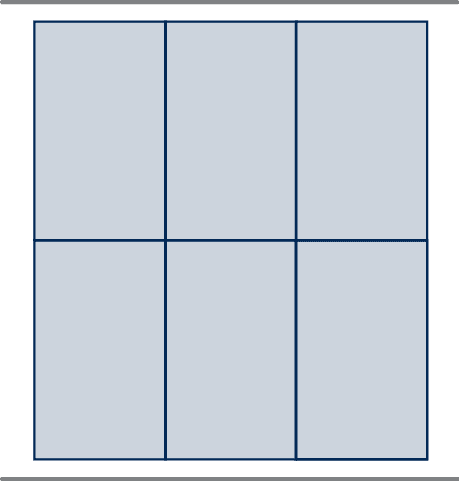

With almost unlimited design versatility, structural glazing has redefined modern architecture. The dream of architects and facade designers of creating a visual impression of a monolithic glass structure has finally come true, thanks to the use of either structural glazing or bolt fixing. Depending on the construction methods applied, there are four kinds of structural glazing:

ADVANTAGES

Structural glazing – Smooth glass surface of facades

In order to achieve the effect of a smooth surface on the façade it is necessary to apply the appropriate construction system. This is known as structural glazing. This decision should be taken at the stage of designing a building.

By the term “ structural glazing” we mean the technology of attaching a glass structure to the building structure, where structural glazing silicon sealant serves as the binding agent.

Structural glazing can be supported, where the dead weight of the panel is transferred by a suitable mechanical support; and is not supported, when the dead weight of the panel is transferred solely by an adhesive

- two-sided systems – using a two-sided structural glazing technique, either the vertical or horizontal joints are adhered to the supporting structure;

- four-sided systems – when using a four-sided system, no mechanical retention is used for the facade panels;

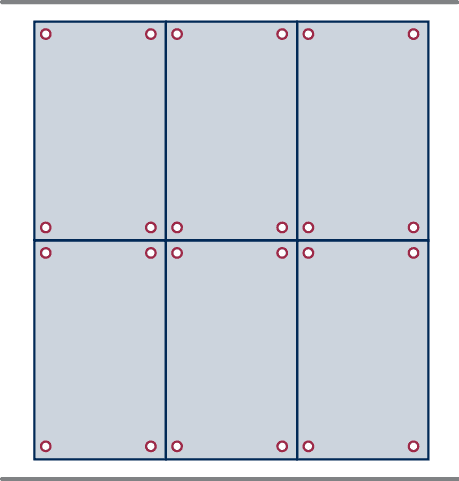

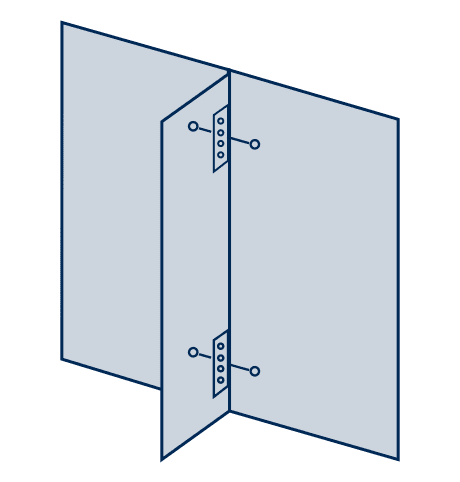

Bolt fixing – Easy mechanical fastening

Structural glazing can be supported, when the dead weight of the panel is transferred by a suitable mechanical support; it is not supported, when the dead weight of the panel is transferred solely by an adhesive.

- bonded fixing systems – in this system the bolts are fixed directly onto the glass via a circular structural silicon seal which acts as a fixing point;

- fin glazing systems – the fin glazing technique employs glass panes which run from the frame of the building, perpendicular to the facade, which is then bonded to the fins using specific structural silicon sealants.

Bolt fixing is a system for securing glazing to a load-bearing structure by means of steel bolts going through the glass and mounted in specially designed holes. Bolt fixing allows designers to create perfectly smooth and transparent glass surfaces making up facades which are virtually invisible barriers between the interior and the exterior space of a building. It imposes no limitations in regards to the height of the building and gives the architects almost unlimited design versatility thanks to the direct fixing of glass panes to a load-bearing structure.

As with the structural glazing, bolt fixing can be used with a variety of glass types e.g. clear, low E passive glass (thermal insulation) and low E solar control glass. Whatever glass type is used, however, it has to undergo heat treatment for greater resistance to thermal stresses.

Requirements

Sealants used in structural glazing have to meet the most stringent requirements for strength and durability. They have to be resistant to ultraviolet radiation and changing weather conditions. Final sealing of the assembled units is made with silicon sealants of similar characteristics to the structural sealants.

Designing glass facades is a task which requires expertise from architects and designers and experience on the part of the technical staff. Therefore, we must warn customers against commissioning haphazard people for mounting and fixing, as the results of this action become evident after a few years and the investor covers the costs.

PRESS GLASS is an acknowledged contractor for fixing structural glazing with Dow Corning as well as Sika sealants.