Insulated units

What is an Insulated Unit?

In modern construction there is a variety of challenges facing transparent wall partitions. Thanks to modern solutions insulated units can help improve thermal performance and protect against noise.

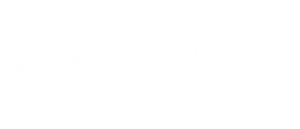

An insulated unit is a hermetically sealed system of glass panes separated from one another with spacer bars and sealed with a sealant.

The space between glass panes is filled with air or argon.

Types of insulated units

Design – insulated unit structure

A double glazed insulated unit is comprised of two glass panes that are connected with spacer and thermally sealed. Typically, one or more of the glass surfaces will have a low-e coating on it, to enhance the units thermal properties. A triple glazed unit is comprised of three panes glass that are connected by two spacer bars and thermally sealed. Triple glazed units will typically have two or more low-e coated surfaces to enhance the units thermal properties.

The space between glass panes is filled with air, or argon, which further reduces the transfer of heat. Protection against gas leaks at the units perimeter is ensured by a spacer bar using, the best warm edge technology, with a two-step sealant process.

Insulated unit structure

Triple unit

Air tightness of insulated units

One of the most significant evaluation criteria for insulated units is air tightness in terms of moisture penetration and loss of the insulated unit’s internal gas, which serves to increase the thermal or sound insulation properties.

The solutions currently employed by PRESS GLASS ensure the superior air tightness of insulated units with spacer bars curved or cut in corners.

Insulated units with warm edge

Until recently, aluminum spacer bars were generally used in insulated units.

However, with ever improving window frame and glazing heat conductivity coefficient values, aluminum bars were shown to be the weak point in insulated unit construction.

Warm edge

Objectives

The generally applied aluminum spacer bars, an essential element in glazed units, have shown to be the weak point in an insulated units efficiency. To significantly increase thermal insulation of that part of insulated units we offer spacer bars called Warm Edge. Our offering includes the most known brands among the Warm Edge spacer bars market.

Range offered

Standard offer

| Type of spacer bar | Color | Widths |

| Warm edge | Black, Grey | 1/2” – 15/16” (12mm – 24mm) |

| Stainless steel | Black | 1/2” , 5/8” (12mm , 16mm) |

| Aluminum | Black, Mill |

3/16” – 15/16” (5mm – 24mm) |

*different colors/spacers available upon request

Download application and watch gallery of warm edges on your mobile

ADVANTAGES

Optimal temperature in rooms

The level and distribution of air temperatures has a significant impact on our comfort while indoors. Until recently it was possible to feel a dramatic drop in temperature near a window during the winter, which could produce a strong feeling of discomfort. Thanks to the application of thermally insulated glass which amounts to 70% of the window surface it is possible to eliminate this problem.

A different problem can arise in the summer, when the sunrays overheat the inside of a building. This problem can be rectified by using low emissivity glass which can help limit overheating while maintaining a high level of light transmission.

Reduction of the linear heat leakage bridge on the edges of insulated unit

The properties of thermally insulated glass are also influenced by the linear heat conductivity on the edges. Up to now aluminum spacer bars have been commonly used, which are essential elements of glass units, but they have proved to be poor in making double glazed insulated units. Aluminum is a much better carrier of heat than the remaining parts of the window construction, so the aluminium spacer bar is the final exit point for heat to move from the interior to the external area. The solution to this problem is to apply a spacer bar known as “a warm edge”, which is made from highly insulating material or precious steel

Limitation of condensation of the edges of insulated unit

The solution to this problem is to apply the spacer bar known as “the warm edge”, which is made of highly insulating material or precious steel. The application of the warm edge improves the thermal insulation along the edges, which in turn increases the temperature in this area and reduces the risk of temporary water vapor condensation.

Reducing the costs of heating

Everyone who receives the heating bill wonders about ways to reduce this expense.

PRESS GLASS perfectly understands these needs and offers a few solutions that make it possible to significantly reduce the costs incurred when heating a building.

High level of light transmission or high level of solar heat gains

Two particularly important characteristics of glass are light transmission and solar heat gains. They have a particular influence on the well-being of people who use the room in question.

As research shows, poor light transmission or over heating in the summer season can be the cause of a bad frame of mind. PRESS GLASS pays particular attention to both of these issues when preparing a product to be offered into the market. In the case of a thermal insulated unit it is necessary to decide what is a more important aspect of wellbeing in each particular building, because there is no possible way to provide a high level of efficiency for both characteristics at the same time.

Summary of advantages

Expand your view

At PRESS GLASS, we manufacture insulated units with maximum dimension 236” x 126”.