Drilling and Milling

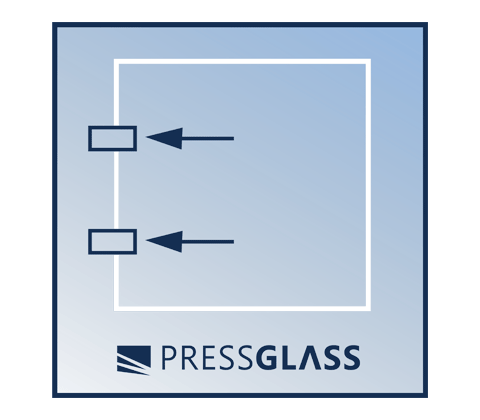

Holes are required in numerous fastening systems. This solution makes it possible for the construction of building elements in which the glass forms flat surfaces and is not disturbed by construction elements.

Making holes also allows for wider use in interiors for instance as decorations. It increases the possibility of creating new solutions of constructions and interior creation by architects.

Creating high-precision notches and grooves with milling is necessary for projects with specific shapes or complex glass-fixtures. Having the ability to cleanly cut glass allows for a variety of aesthetic interior and exterior possibilities.

Advantages

Market Offering Includes Panes:

Available Dimensions

| Machining type | Glass thickness |

Minimum dimensions |

Maximum dimensions |

| drilling/milling | 3/16” – 3/4” (5mm – 19mm) | 4” x 12” | 126” x 236” |

Additional Order Requirements

In the case of orders for insulated units or tempered glass with drilling work, remember that before starting the tempering process, the glass must undergo the drilling process. All details of drilling work have to be stated in the order, enclosed as drawings and tables with all the required data.